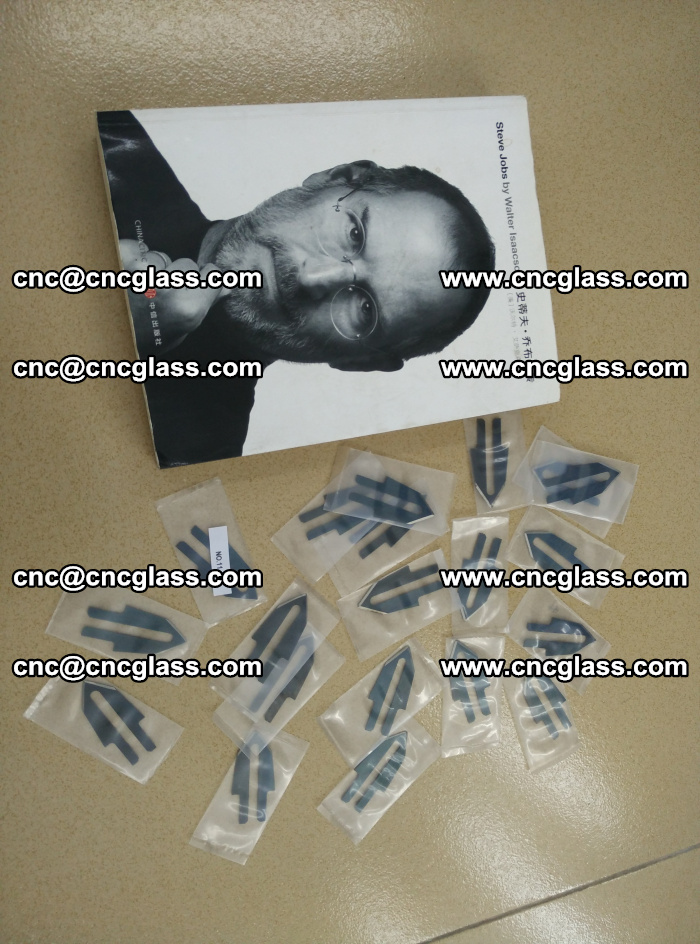

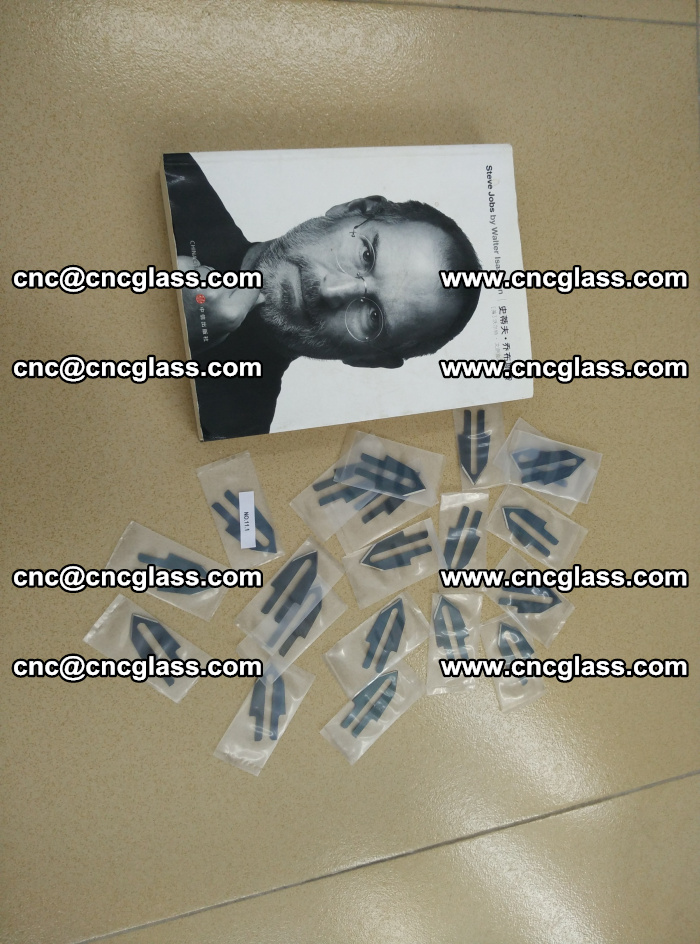

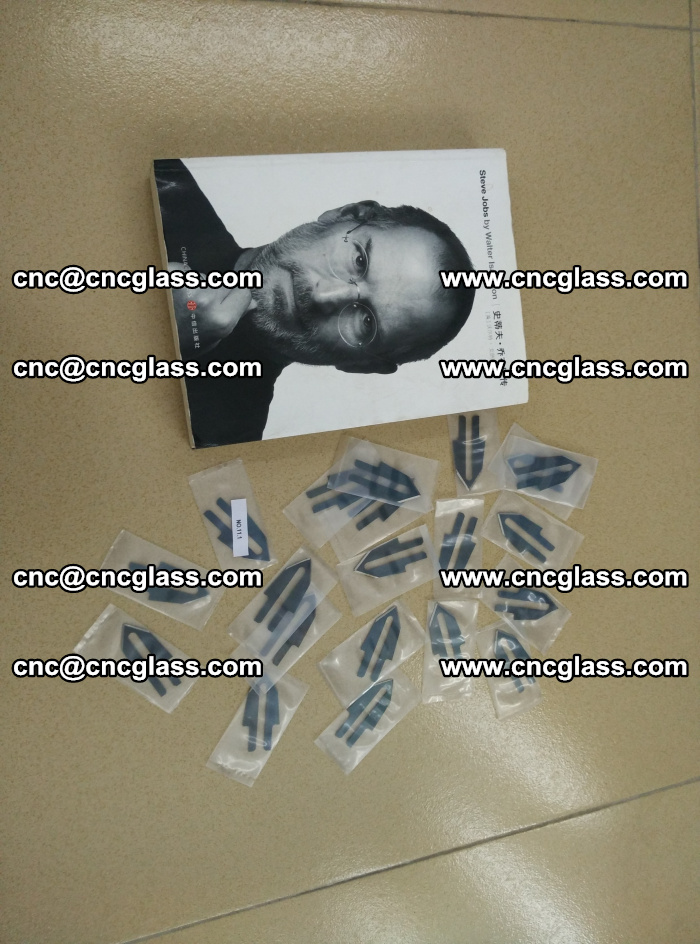

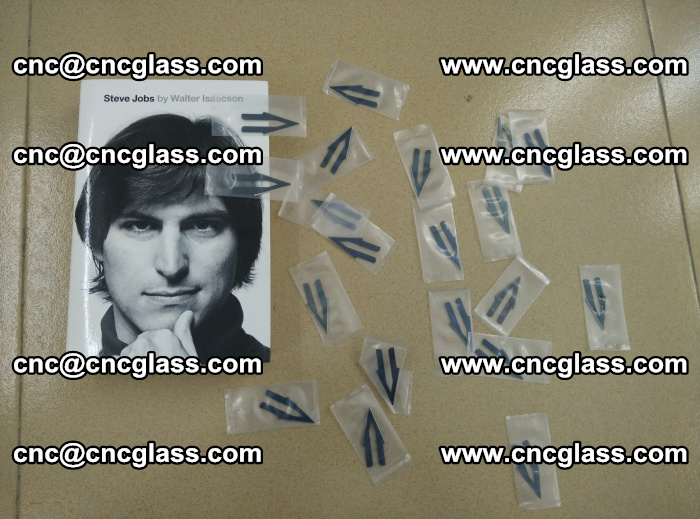

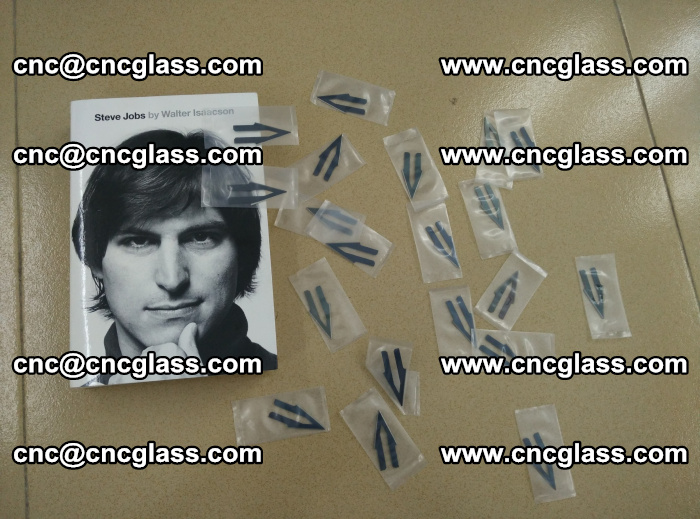

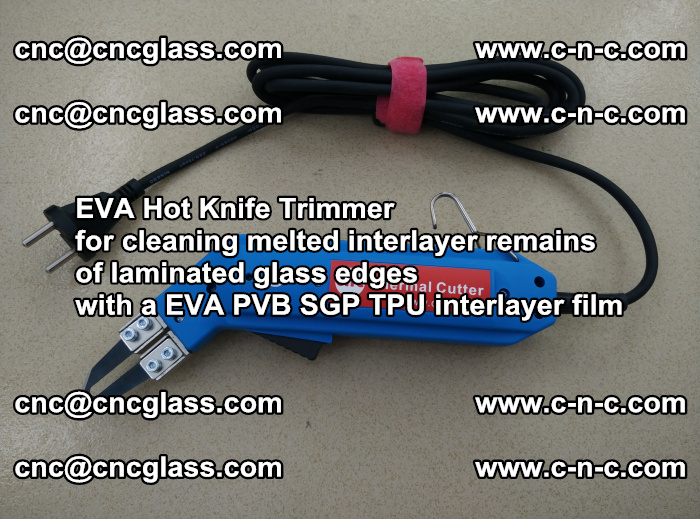

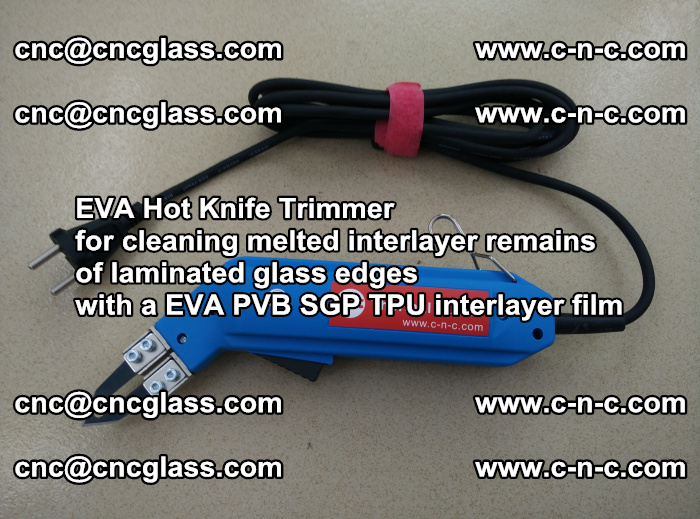

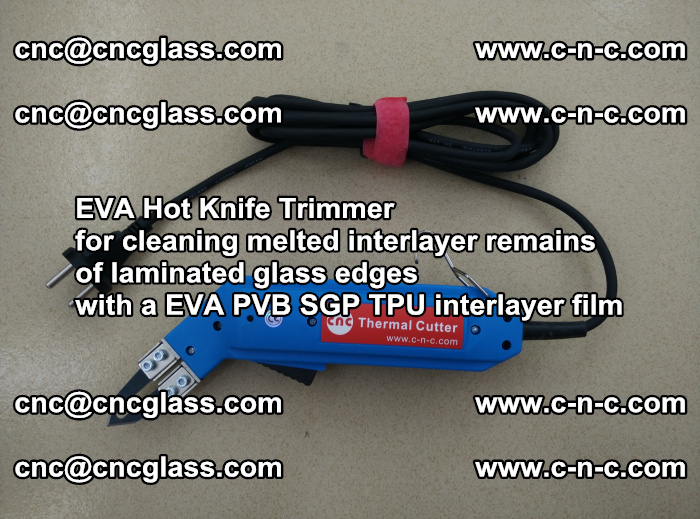

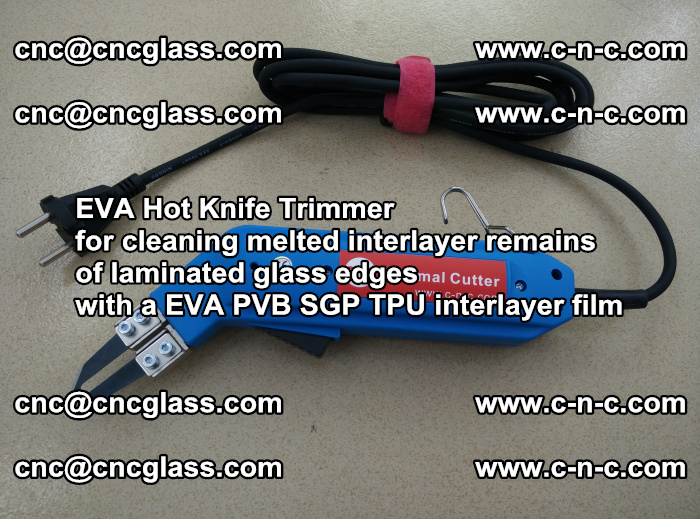

Thermal cutter trimming EVA PVB SGP overflowed remains

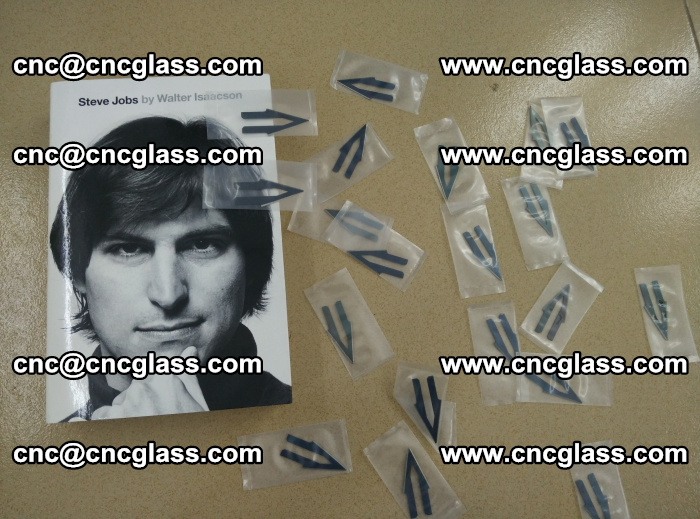

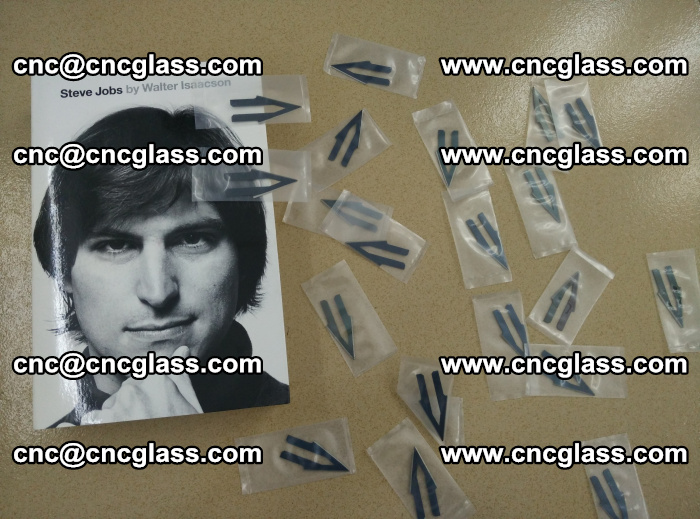

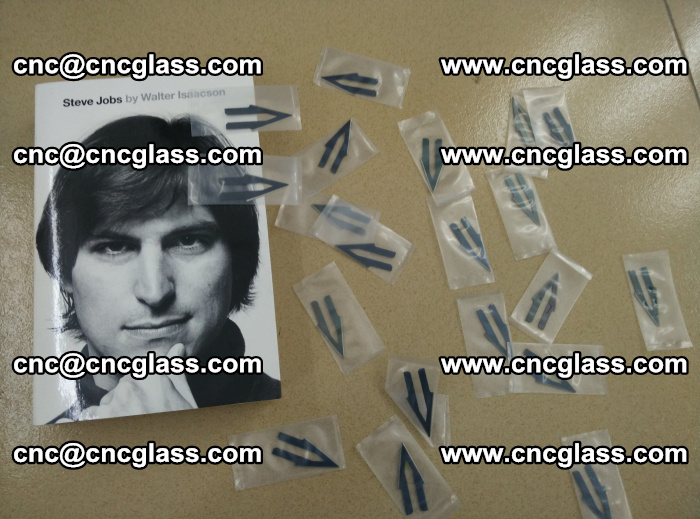

Blades of hot knife trimmer for eva interlayer film glass laminating

To prevent fire / explosion hazard of the safety laminated glass machine with EVA film

1.1.4

To prevent fire / explosion hazard, should take the following

Equipment in accordance with the intended use of the proper, prohibition of the use of volatile organic compounds containing liquid glue. This equipment is prohibited for non-intended use of the occasion (such as for baking, drying fluids containing volatile organic glue, etc.), otherwise there will be a risk of explosion。

Do not put flammable equipment nearby, do not store film in the vicinity of equipment, or may cause fire.

Equipment laying the ground attachment to the table should not be able to burn.

When equipment fails, or shows abnormal signal, please disconnect the power immediately, or it may cause the electrical malfunction in the fire.

Do not plug the hole cooling boxes to foreign body into the electrical box.

Thermal Cutter Trimmer for cleaning interlayer remains of laminated glass edges with a EVA PVB SGP TPU interlayer film

Cautions of EVA film safety gazing vacuuming machine

1.1.2

The prevention of injury, should take the following:

For equipment operators should be subject to induction training, with equipment operation skills, be able to correctly understand this statement and other random information.

The operator to enter the workplace should wear insulated shoes, do not wear loose clothing style.

And the operator to wear protective gloves to prevent hand touching glass and glass-plastic folder which has not been fully released after cooling.

When heating and vacuum process work, don’t put hand on the door of vacuum pump, to avoid high-temperature hot.

The interlayer film materials to be processed should not release toxic, and irritating smell of gas. Otherwise, there should be adequate protection measures to prevent inhalation of these harmful gases, such as to exhaust harmful gases into the appropriate place.

When open the door of the furnace, in order to avoid excessive inhalation of the odor release, you should appropriate wear masks.

Take-off and landing with forklift loading and unloading of glass should be careful not to hand on the rope and the rope round.

When cooling fan working, don’t put hands on the cooling fan.

High maintenance to pay attention to safety, take prevention measures to prevent the fall. Care staff if necessary.

The operation of the collision is to be careful to pay attention to avoid the hook. hook loading construction should remove to the highest position

In order to avoid loading and unloading by forklift fork arm tripping over, don’t use loading and unloading forklift truck, the fork arm should be moved to the lowest position. At the same time, should also be noted the lower car to prevent tripping.

Equipment containing asbestos insulation materials, insulation materials in the replacement or removal of equipment at end-of-life, measures should be taken to wear appropriate masks, protective clothing and gloves and work shoes, to avoid direct contact and inhalation of asbestos dust.

EVA PAD FOR SGP PVB EVA TPU SAFETY GLASS SEPARATION

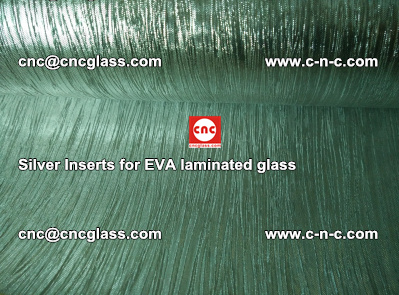

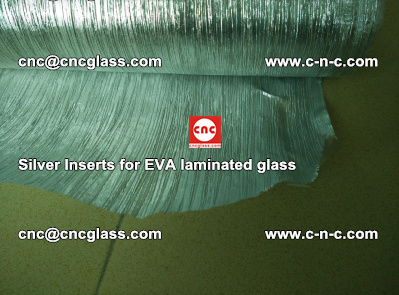

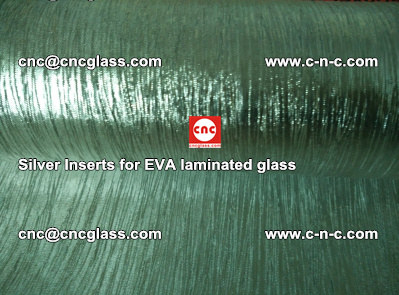

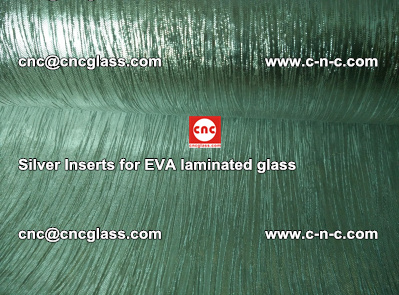

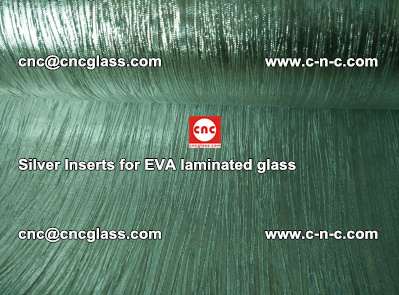

Silver Inserts for EVALAM interlayer film laminated glass

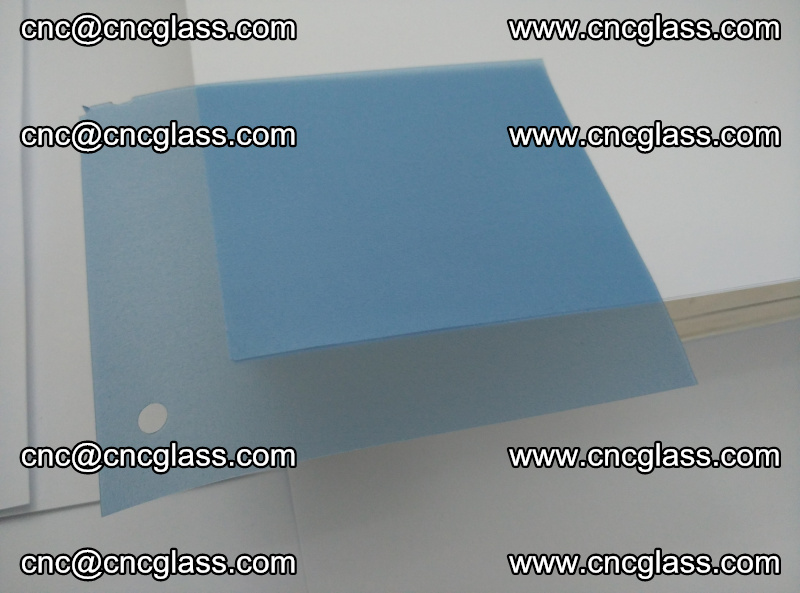

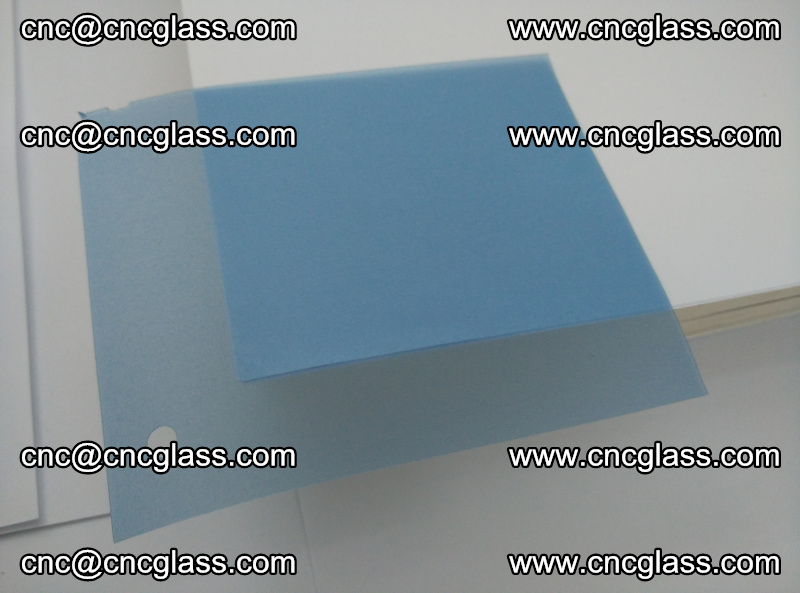

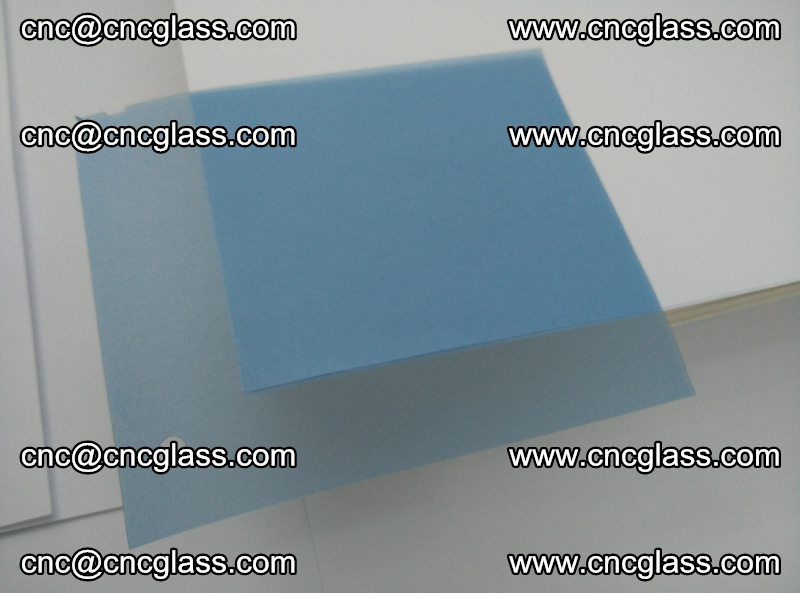

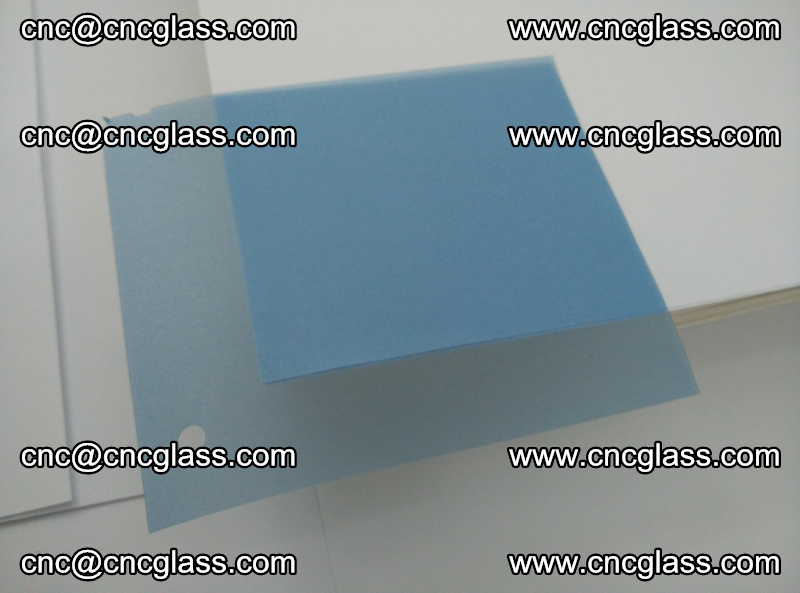

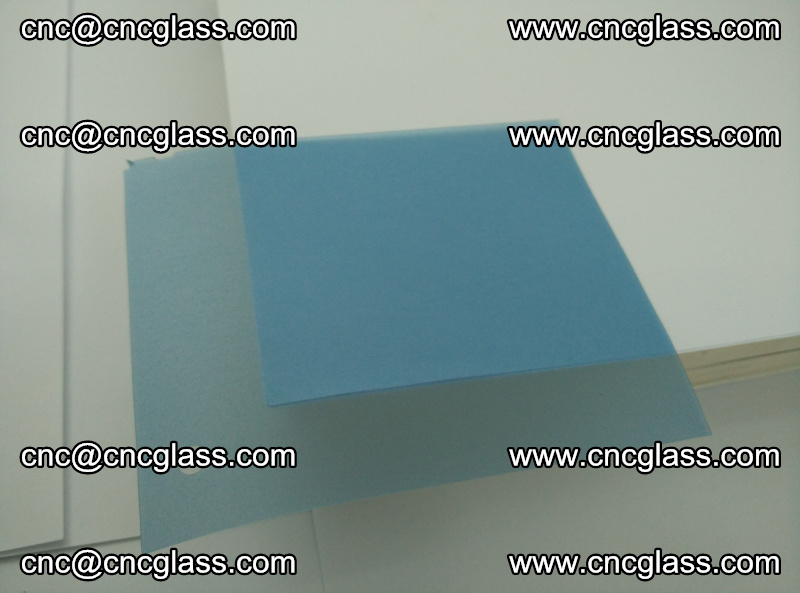

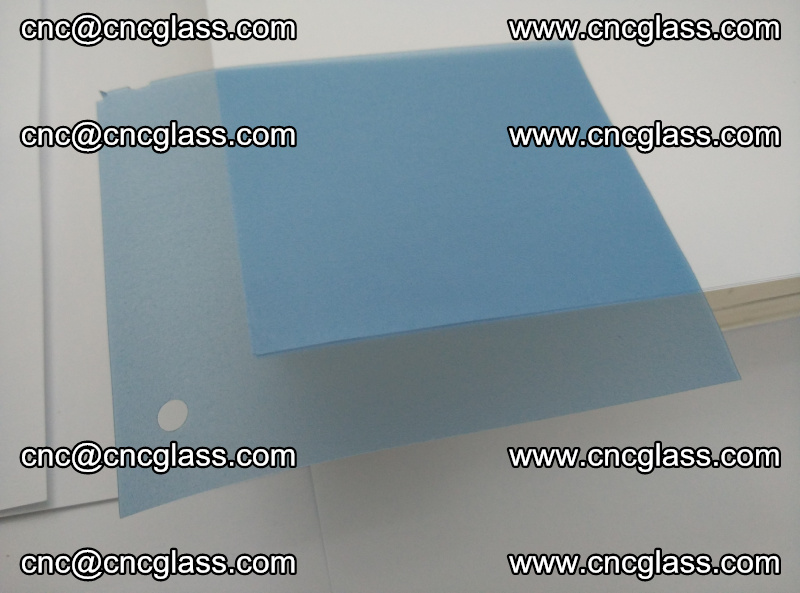

Ethylene Vinyl Acetate EVA Interlayer Film for Laminated Glass

EVA Film:

EVA stands for Ethylene Vinyl Acetate Copolymer, a copolymer resin used in the production of laminated glass as the interlayer film sandwiched between two pieces of glass, like PVB Interlayer Film, and SGP Interlayer Film. The main function of the interlayer is to stick the two piece of glass together, in order to make the sandwiched glass safer and more secure.

EVA Film performs excellent in bonding strength, heat resistance, cold resistance, humidity resistance and tensile strength in laminated glass. It has been partly taking the places of PVB film in laminated safety glass, laminated art glass, and laminated color glass.

EVA film is not adhesive at room temperature. After heating, it melts and has cross-link reaction. In the production of laminated glass with EVA interlayer film, no autoclave, roller press, air bag, or vacuum rubber ring is required. As EVA interlayer Film can be processed under normal climatic conditions, no clean room with climatic control is required in PVB lamination. And the laminating machine line of laminated glass with EVA Film is less cost and easier to install. All laminating processing will be finished and completed in one vacuum laminator. EVA Film for laminated glass has excellent transparency, outstanding adhesion and aging-resistance (more than 15 years), can be used for architectural glass, decorative glass with fabric, privacy glass, auto glass etc.

Advantages of EVA film :

– High tensile strength

– Excellent transparency

– Outstanding adhesion

– UV protection

– High impact resistance

– Good temperature withstanding

– Water proof

– Humidity durable

– Long-term reliable (long-term aging resistance)

– Sound barrier

Names of EVA FILM for Laminated Glass

Some will call EVA Film in different name:

-laminated glass eva interlayer

-ethylene vinyl acetate film

-solar eva film

-glass lamination film

-glass laminating film

-laminating film rolls

-lamination film

-safety glass film

-tempered glass film

-security glass film

-glass eva film

-laminate film

-security laminate film

-decorative glass film

-stained glass film

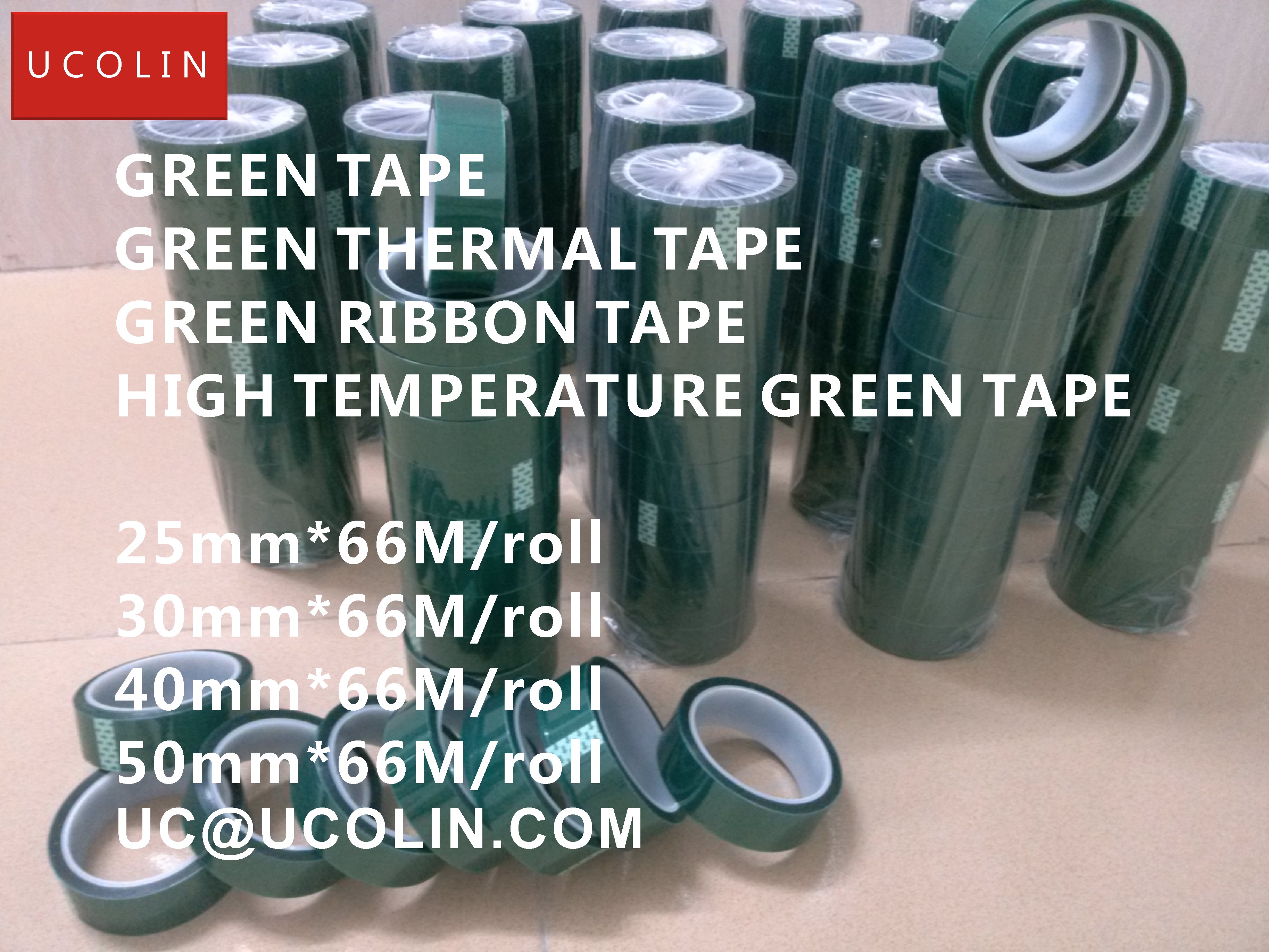

Silicone Adhesive PET Green Tape for Masking for Powder-Coat Painting

Silicone Adhesive PET Green Tape for Masking for Powder-Coat Painting

• Masking for powder-coat painting.

• Flash-breaker tape when pulling through cured coating such as epoxies.

• Holding and splicing difficult to stick to surfaces such as silicone liner.

• Holding parts or sealing vacuum bags during processing.

* 3M equivalent Single Sided Polyester Tape

* Polyester film offers excellent thermal,abrasion,and chemical resistance

* Green color makes tape placement obvious for both application and removal.

* Silicone adhesives adhere well to tough-to-stick to surfaces like silicone liners

* Silicone Adhesive removes cleanly from many surfaces

PET Green Tape for Electrical Appliance Touch-Screen Display

PET Green Tape for Electrical Appliance Touch-Screen Display by ZAC LYNN-UCOLIN

Purpose:

Suitable for using in the production and process of electronic products, electrical appliance and touch-screen display,

hot drilling process etc.

Composition:

Backing material: High quality PET polyester film

Adhesive: High performance improved acrylate and organic silicon pressure sensitive adhesive