Color Pvb Film -Milky White

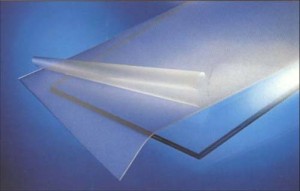

Polyvinyl Butyral PVB Interlayer Film Products:

Product Description

Color PVB is normally used on building glass for safety and decoration

Thickness (mm): 0.38~1.52

Width (m): 0.6 to 2.44

Length (m): 200~400m

Packing: PE foil

We can produce special model according to your requirement.

Colour PVB film used in building safety glass.

Available color: Purple, brown, milky white, red, black and more

PVB packing: Aluminum foil and vacuum

PVB color film is a new patented film

It can be widely applied in laminated safety glass

Construction and fuction:

Baizan PVB interlayer is a macromolecule material molded by polyvinyl butyral resin that is plasticized and extruded by plasticity.

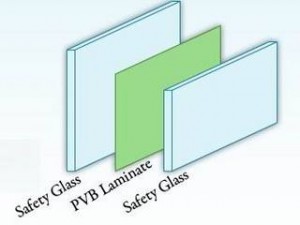

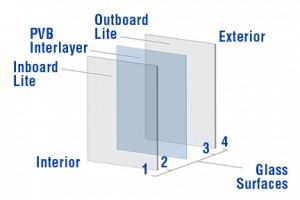

Laminated safety glass is a special glass which inserts the PVB film between two pieces of common glass

It can filter 99% of the ultraviolet light thereby helping to avoid direct sunlight and delaying the aging and fading of interior decoration to prolong its service life.

When it is collided with other blocks, the PVB film can offset the compact pressure and keep the glass from shattering and the people from dangers

Feature: Noiseproof, light-controlling, thermal-resistant, anti-penetration, structure integrality

Quarantee period: Well-stored and under normal temperature, the product has a quality of guatantee of 2 years.

Polyvinyl Butyral PVB Interlayer Film Manufacturers:

Company Name: Tiantai Baizan Plastic Co., Ltd.

Company Address: Eyuan High-Tech Industrial Zone,Tiantai, Taizhou, Zhejiang, China

City/Town: Taizhou

Province/State: Zhejiang

Country/Region: China

If you need any help in China to find the information of glass lamination materials, products, manufacturers, Suppliers, Offers, Please feel free to contact us, we will answer you in 24hours.

Mail: helps@glasshelps.com

China GlassHepls Service Center of Glass Materials Purchase